BUHLER BELT CONVERSION PARTS FOR AIRTRONIC ROLLERMILLS Admin Edit

Contact: bart@usedflourmachinery.com Mobi:0086 185 3712 1208

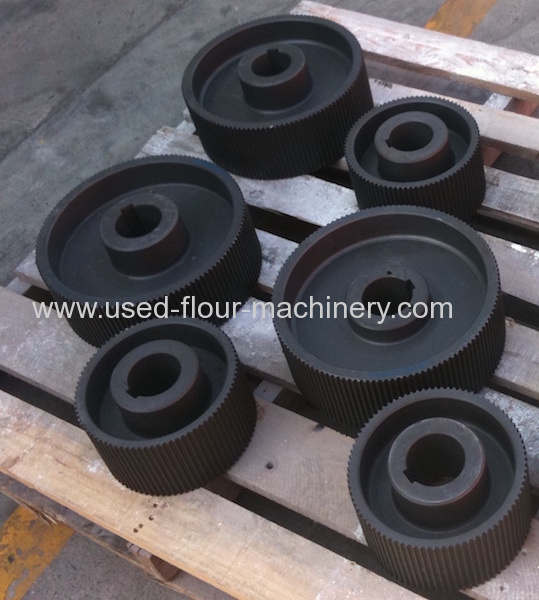

More close photos of Retrofit Belt Drive for Airtronic Roller Mills MDDK and MDDL

Your benefits

- Easy conversion

- High power

- No gear oil and therefore excellent sanitation

- Easy maintenance

- Simplified roll changes

- Snub wheel with for-life-lubricated bearings

- No different gearwheels required for rolls with reduced diameter

- Only one belt type for all transmission ratios

The new belt drive for the MDDK/L roller mill offers substantial advantages over the gear drive version (see box at right).

This power transmission is easy to install and makes maintenance very much easier and more cost efficient.

Buhler scope of supply:

The retrofit kit is supplied complete with all the components required for installation, including conversion instructions.

The assembly kit includes 1 spare belt. For the conversion, one installation set is required per plant.

The price does not include installation.Time requirement for conversion is two to three hours per roll pair.

CAUTION: Applies to MDDK/L

The roll speed must be checked for the correct torque and if necessary be modified at the drive end. Graphic 1 shows the minimum speed, which must always be reached. If the roll motor power is known, it will be possible to derive the speed. If the speed is too low, this will reduce the belt service life.

CAUTION: Applies to MDDL

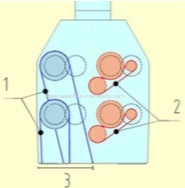

In order to prevent a collision between the drive belts of the top mating pass (1) and the transmission (2), the drive belt must not go beyond the center (3) of the roller mill (Graphic 2). If necessary, the drive motor may have to be slightly moved.

Graphic 1

Graphic 2

Related Links

Category: Buhler MQRF46/200 Purifier Spare Parts

Related Category: Buhler Cleaning Machines Spare Parts Buhler Rollermill Spare Parts Buhler Plansifter Spare Parts